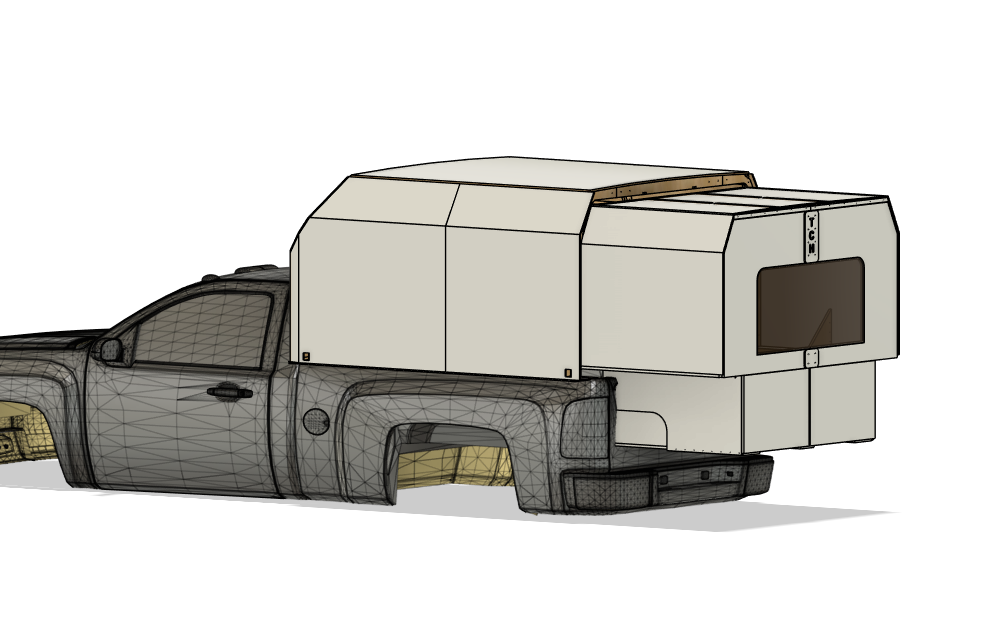

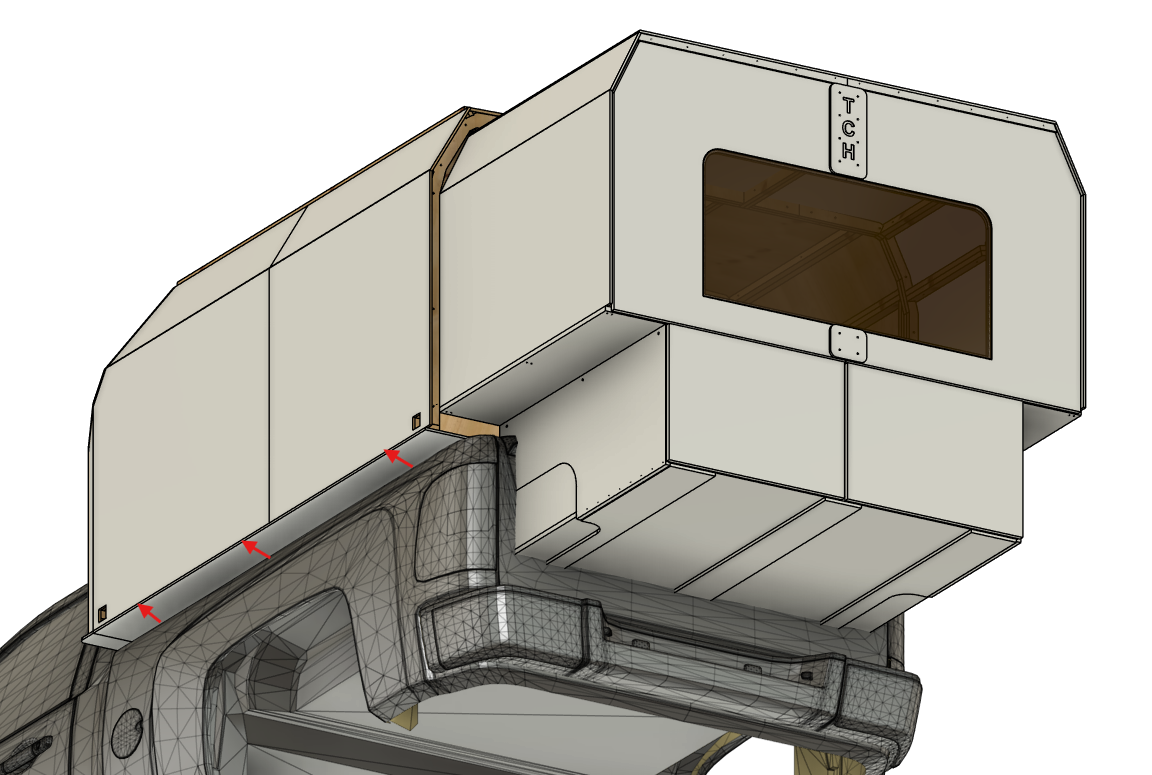

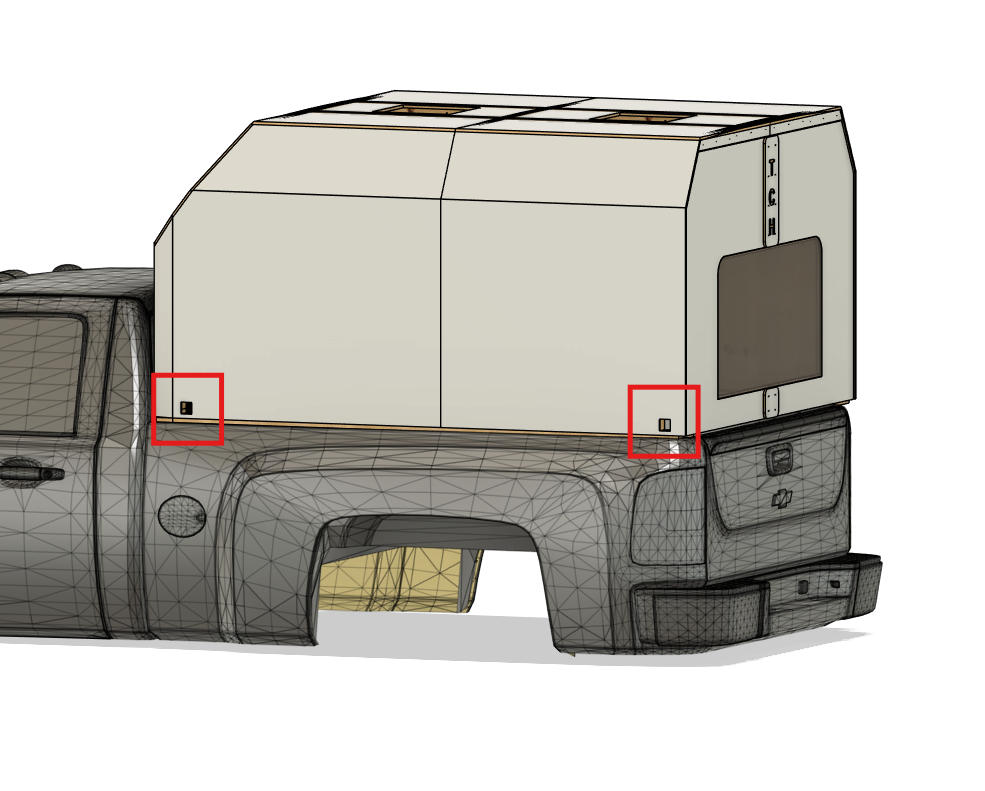

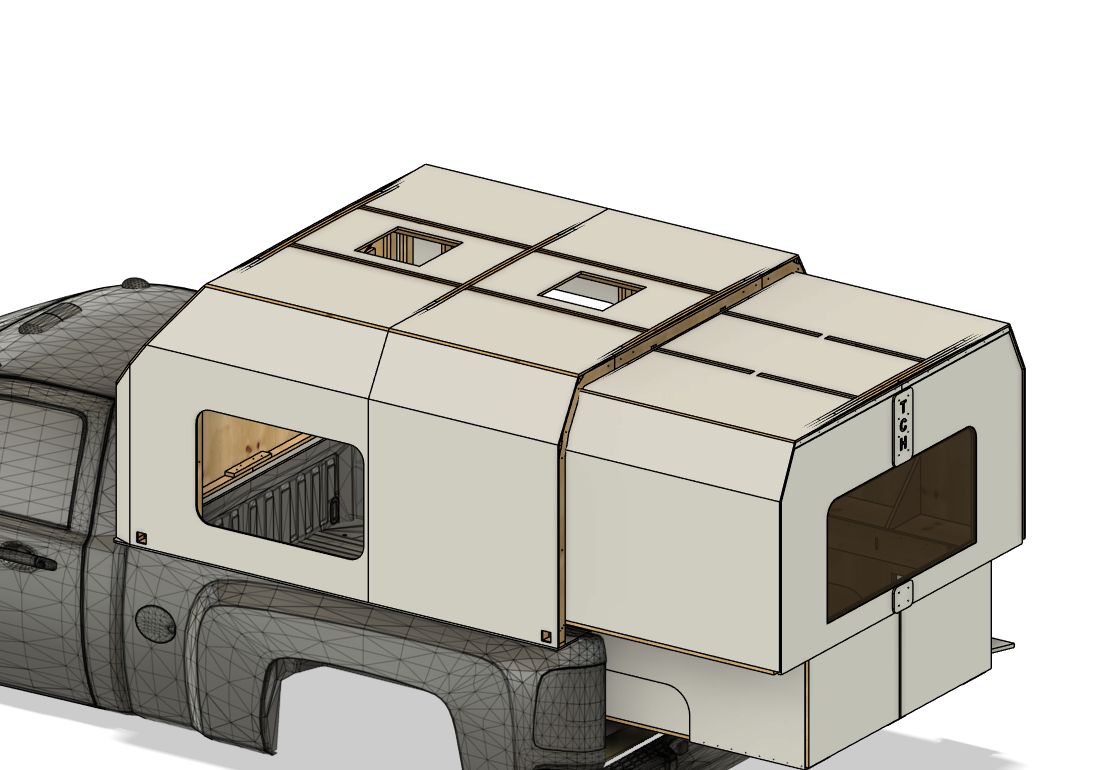

Truck Camper Hybrid is a patented (US 11,440,387) truck camper shell system that works on any truck with horizontal bed rails. Our patent distributes the weight of the shell system between the truck bed rails and bed floor allowing us to expand wider and longer than the side bed rails. This is the reason for the Hybrid in our name, we’ve combined the best parts of a slide-in, truck cap, and pop up into something brand new.

Our Unique design

I’ve been a part of the fiberglass truck cap camping movement since the year 2000 when I purchased my first truck out of college. However, once I got married and started having kids, this design no longer worked for our family, and my wife had some strong opinions on my builds. Instead of abandoning fiberglass truck caps or ignoring my wife, I started thinking of ways to improve the design. How could I make a hard sided shell system that would go longer and wider like a slide-in truck camper while staying well within the payload limits of my truck? Read more…

maker’s edition

We are calling this first release of Truck Camper Hybrid the Maker’s Edition because we want to empower all the Makers to help us bring this to market. I cut the first two truck campers using a 4ft by 4ft hobbyist CNC that I learned how to use at my local makers space. While learning how to cut parts on a CNC is not for everyone, we are offering various levels of DIY. Just want someone to build it for you? No problem, we can fully build one for you or point you to a local Maker who is building these to our standards. We think that our fully built campers are still the highest quality, least expensive, and most spacious truck camper offering in the industry. Read more…

Start Building yours

Choose an outer shell

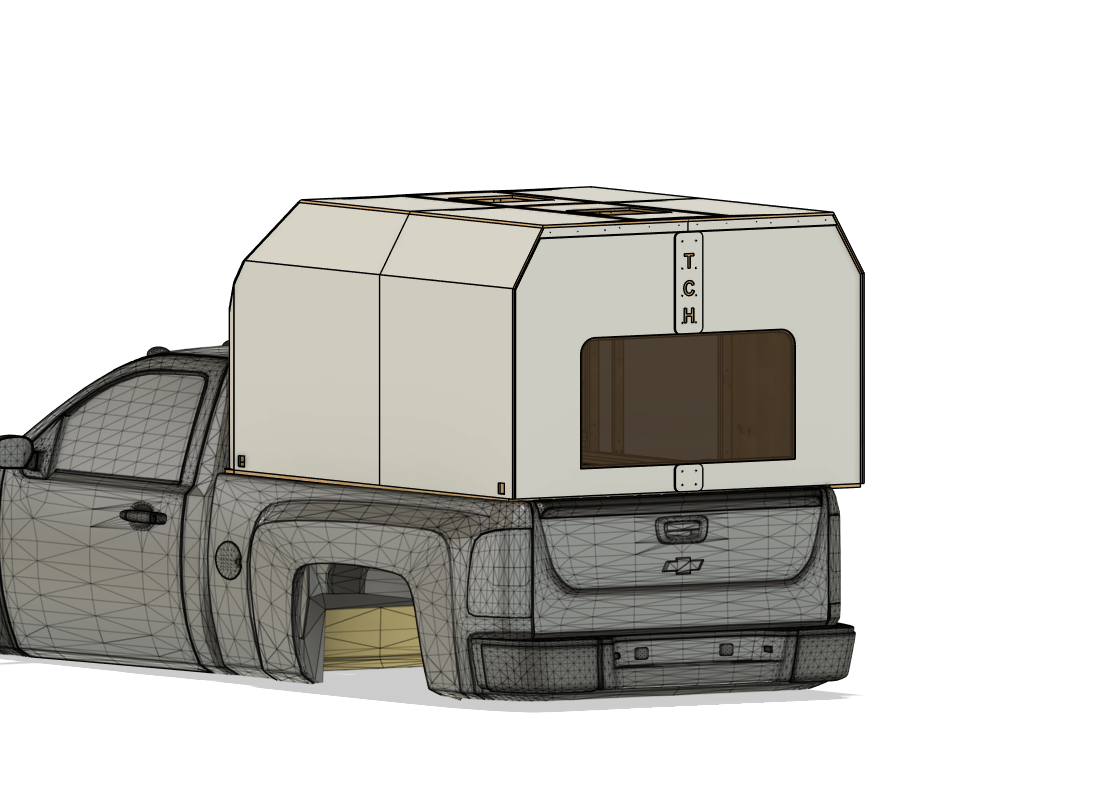

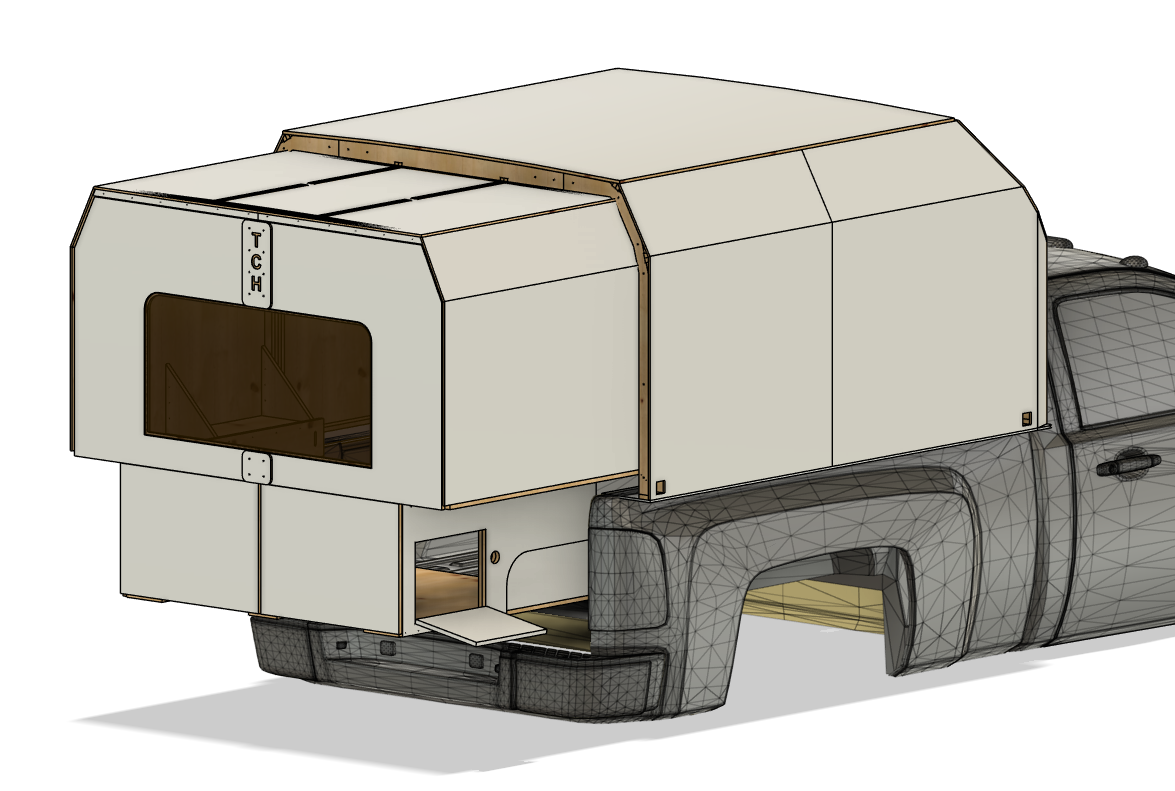

Nose Over

If space is a high priority, you will want to consider the nose over the cab model. This option will cost more and is more difficult to build, but we are here to help. All those really cool angles in the nose will turn a lot of heads. We put two kids beds in the nose and store all our bedding there while driving or hanging out.

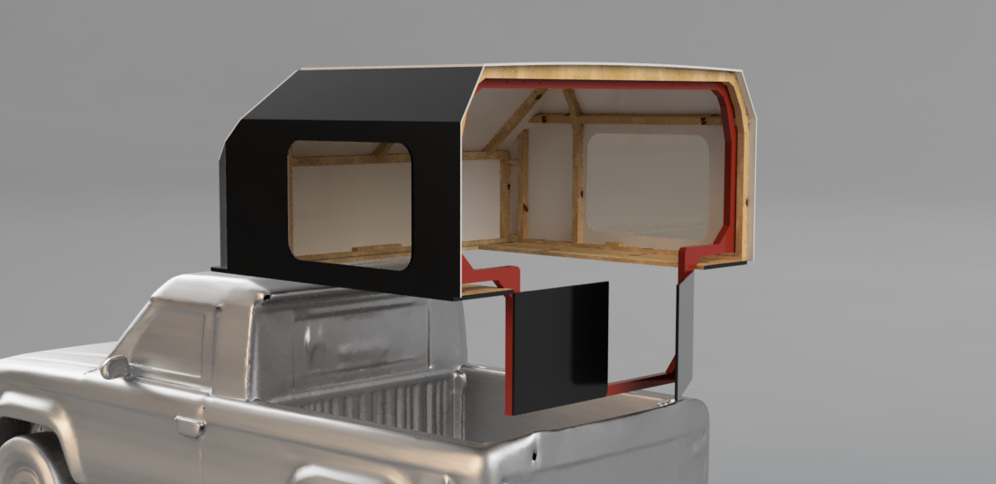

noseless

Want to use a roof rack, keep your build simpler, and costs down? You can start off with a noseless shell. It’s still going to be bigger, more customizable, and just as light as any fiberglass shell on the market.

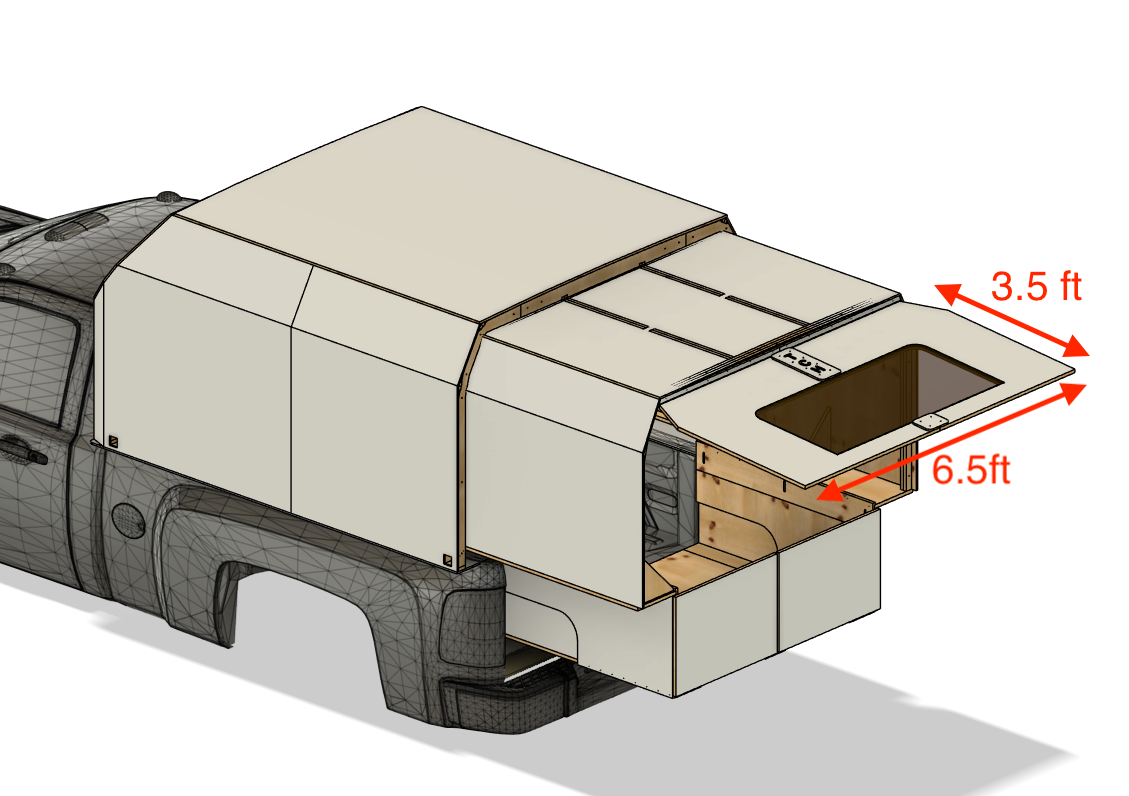

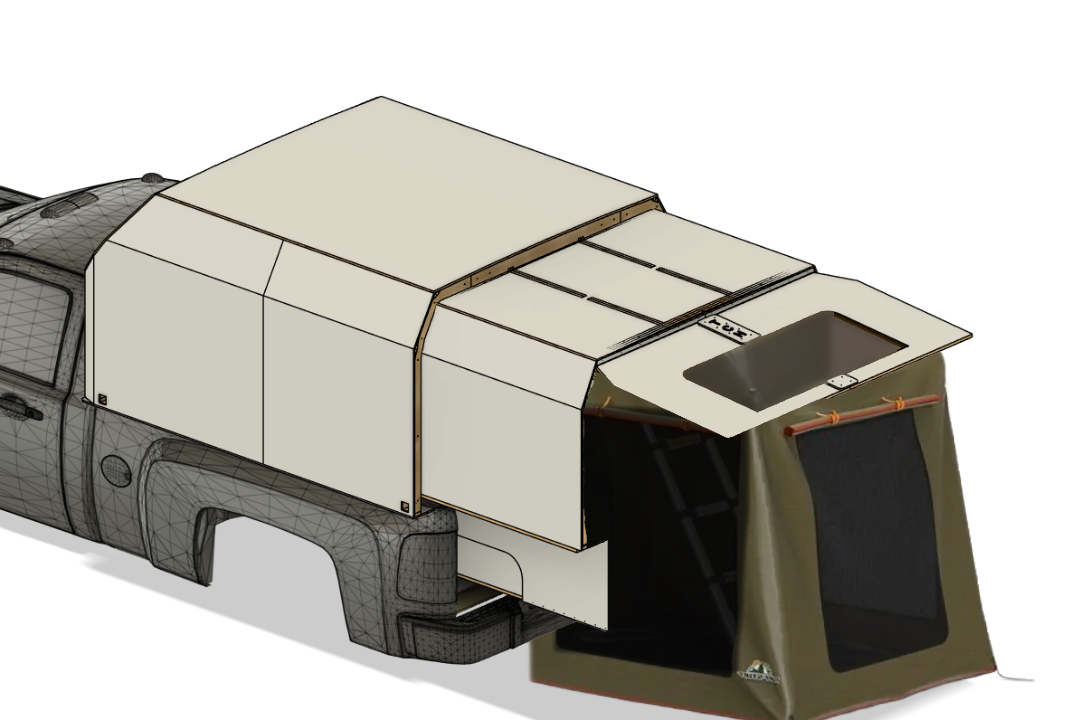

2. Choose a Slide option

Parametric model

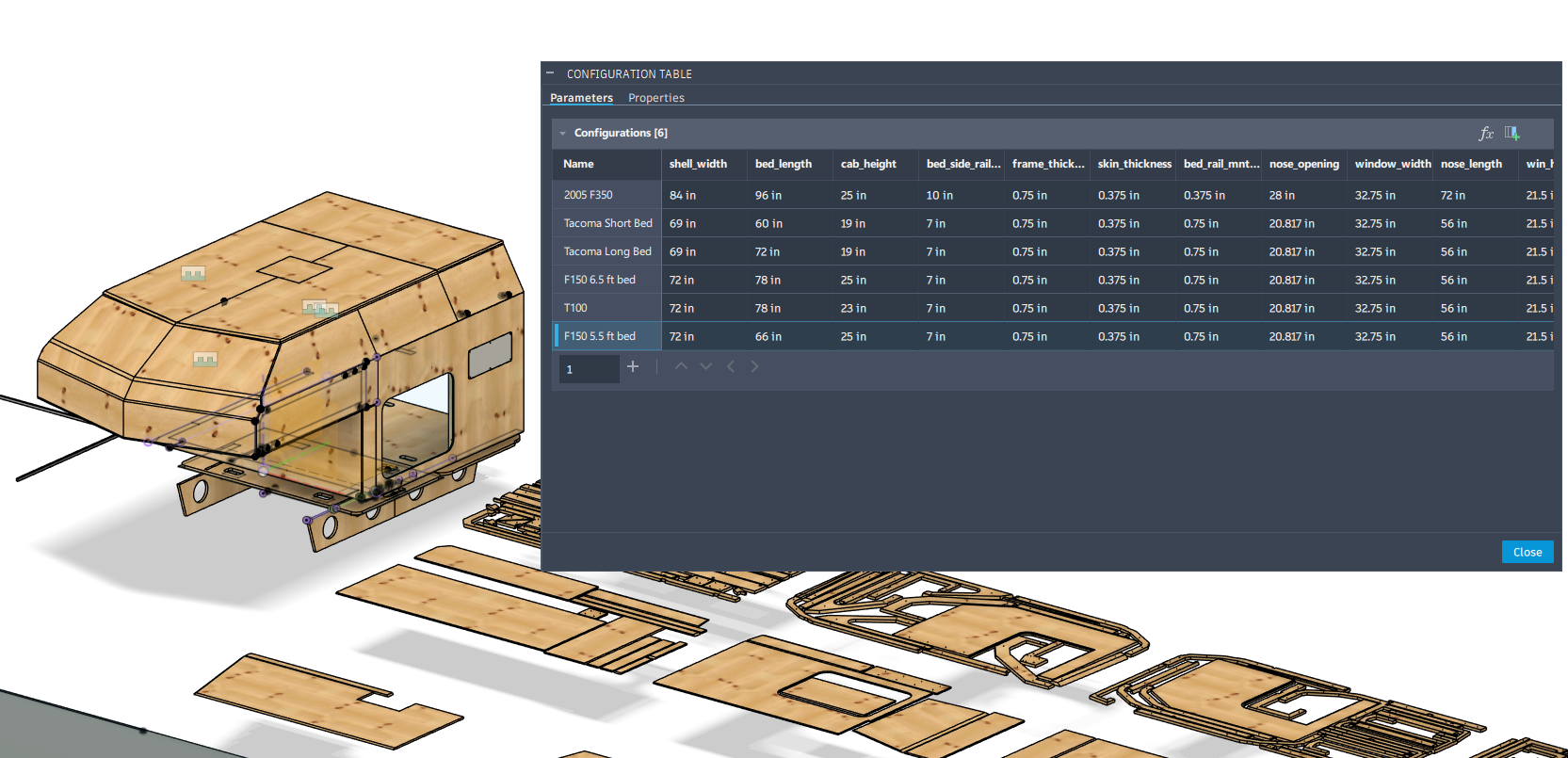

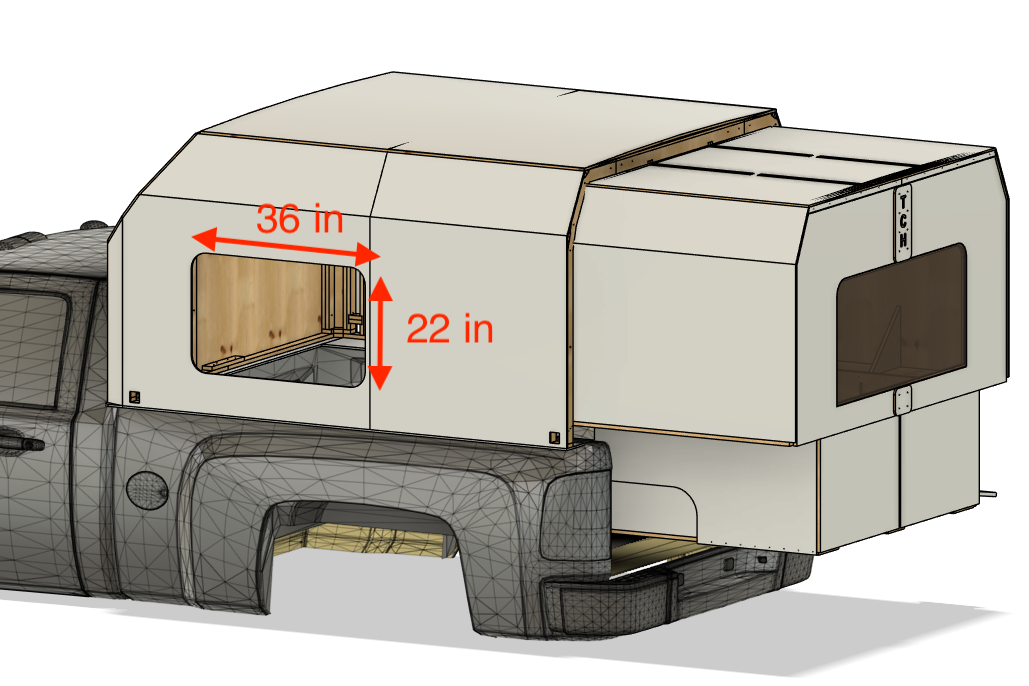

Every Camper is different. This is why we’ve invested so heavily in our 3D parametric model that can handle just about every truck on the market with horizontal bed rails. Look through the carousel of visuals below to get some ideas of what we currently offer.

3. Choose features

Pricing

Our target market is the family interested in a pop up camper because of their large space and affordability. My goal with the Makers Edition is to keep the price of a truck camper lower than a pop up while offering the same space at a higher quality. The secret to our success lies in an overlooked and misunderstood material that is often looked down upon, plywood. Once we got the water protection of the CNC cut plywood figured out, we knew we found our niche. The best thing about partnering with Line-X to protect and seal our campers is that it makes the entire DIY process that much easier. This frees you to focus on what you love to do whether that is learning to CNC machine, put together a kit, building out the interior, or enjoying more time camping.

Because our campers are designed using advanced 3D Design software, we are able to quickly estimate cost and weight based on all your parameters. The software knows how to layout all of the parts efficiently on 4 by 8 sheets of plywood readily available at your local box store. See the pricing video below where I break down the different levels of cost based on your level of DIY. Even the price of the fully built (no DIY) shell system comes out below most of the new pop up campers on the market. Please keep in mind we no longer recommend a DIY paint job, this should be left to the professionals like Line-X.